Carbon Capture, Utilization and Storage (CCUS) Technologies: A review

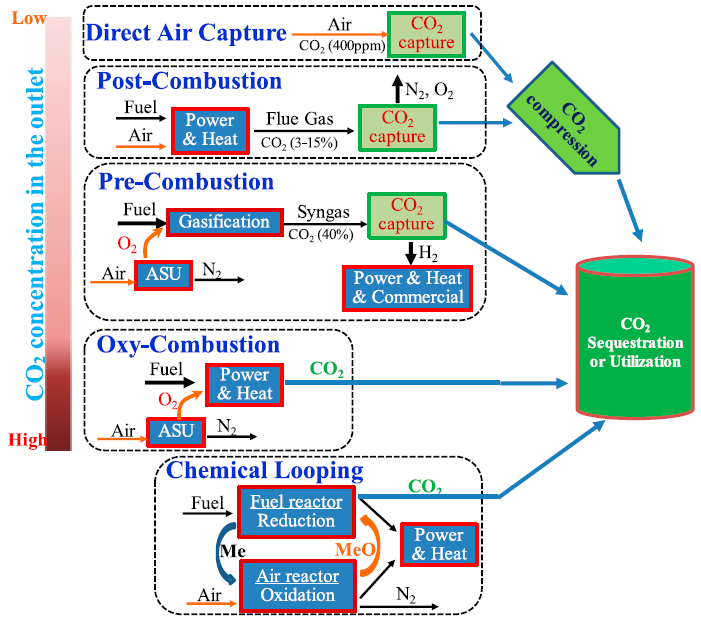

With growing levels of CO2 in the atmosphere due to several anthropogenic activities taking place simultaneously across the world, climate change and reducing carbon emissions have become critical. Therefore, several industries and researchers are continuously working on the entrapment of carbon emissions using multiple state-of-the-art technologies. The umbrella of technologies that aid in decreasing carbon emissions is collectively known as Carbon Capture, Utilization, and Storage (CCUS). Among the different technologies, the widely analyzed are post-combustion capture, pre-combustion capture, oxy-fuel combustion, chemical looping, and direct air capture.

So, what are the differences between each technology?

- Post-combustion capture

During this process, the flue gas with a low concentration of CO2 (3-15%) that is emitted after the combustion of fuel in the presence of air is passed to a CO2 capture unit which commercially runs based on amine-based scrubbing to absorb CO2. Once the amine and CO2 come in contact with each other the amine-based solvents absorb CO2 and therefore, the CO2-lean flue gas can now be emitted back into the air with significantly lesser amount of CO2.

- Pre-combustion capture

In this process, gasification and steam reforming of fuel feedstocks including coal and natural gas are utilized to produce syngas (CO and H2). Water then converts the CO into CO2, producing more hydrogen, and a carbon capture system is used to separate the CO2 by absorption, adsorption, or membrane-based systems. The hydrogen-rich gaseous stream can then be used for fuel cells, gas turbines, and boilers.

- Oxy-fuel combustion

For this system, the fuel source is combusted in the presence of pure oxygen which is obtained from air separation units (ASU). By burning the feedstock using only oxygen high concentrations of CO2 are produced which can then be directly sequestrated. However, this particular technology is limited by the expensive nature of running a cryogenic air separation unit.

- Chemical Looping

An emerging technology that utilizes an oxygen carrier such as Fe, Mn, Cu, Ni, and Co metals to oxidize in air using an “air-reactor” to form a metal oxide which later undergoes reduction with a hydrocarbon fuel in another reactor to regenerate the metal and release CO2 and water. After, the cycle is over the metal is returned to the air reactor to begin the next cycle. The air-reactor which is exothermic produces heat and power which can be used for other purposes while the CO2 that is released sequestered.

- Direct Air Capture

As the name suggests this particular technology aims to reduce the CO2 present in ambient air. To decrease the CO2 levels large volumes of air are expected to flow into the DAC system using fans and as the air comes in contact with an adsorbent the CO2 is trapped while the rest of the air can flow out. Once the adsorbent is saturated, it is regenerated to obtain CO2, and the adsorbent is used once again for the next cycle. However, the immense infrastructure required to set up a DAC system and to selectively reduce CO2 in such dilute concentration (~420 ppm) in the presence of other gases makes the technology challenging. But countries like Iceland have now started to establish DAC facilities at a large scale.

In this post, we explored the potential of adsorbents that can be applied for carbon capture and storage but stay tuned for our next article where we will focus on the application of catalysts that can convert CO2 to useful products!

#catalysts #adsorbents #CCUS #carboncapture

Picture taken from: Wang, X. and C. Song, Carbon Capture From Flue Gas and the Atmosphere: A Perspective. Frontiers in Energy Research, 2020. 8.